Magnetic Rope Testing

Effectively detect internal and external defects in your wire ropes

Our MRT service

In 2020, to provide an effective solution to ensure the safety of professionals and reduce their production downtime, Traction Levage created its MRT service.

This service is characterized by its independence from the historical commercial service, allowing it to travel all over the world to operate directly on-site.

Magnetic Rope Testing

Magnetic Rope Testing (MRT), is a wire rope inspection method that uses the ferromagnetic properties of wire ropes to detect external and internal broken wires, deformations, and corrosion.

Advantages:

- Non-destructive method

- Detects external and internal wire rope defects

- Recommended for non-rotating wire ropes

Our technical experts, qualified in wire rope kinematics studies and certified MIT Level II in Magnetic Rope Testing, are available to design an MRT solution tailored to your situation.

The advantages of the Magnetic Rope Testing

![]()

Non-destructive method

![]()

Fast magnetic rope testing

![]()

Detection of internal and external wire ropes defects

![]()

Reliability of the results

How does the MRT inspection work?

The wear of a wire rope often begins on the inside. Even when defects are located on the outside of the wire rope, they are usually covered with grease or dirt.

Considering these parameters, is a simple visual inspection sufficiently accurate?

Discover in this short animation how the Magnetic Rope testing inspection works and how our devices can effectively detect internal and external defects in your wire ropes.

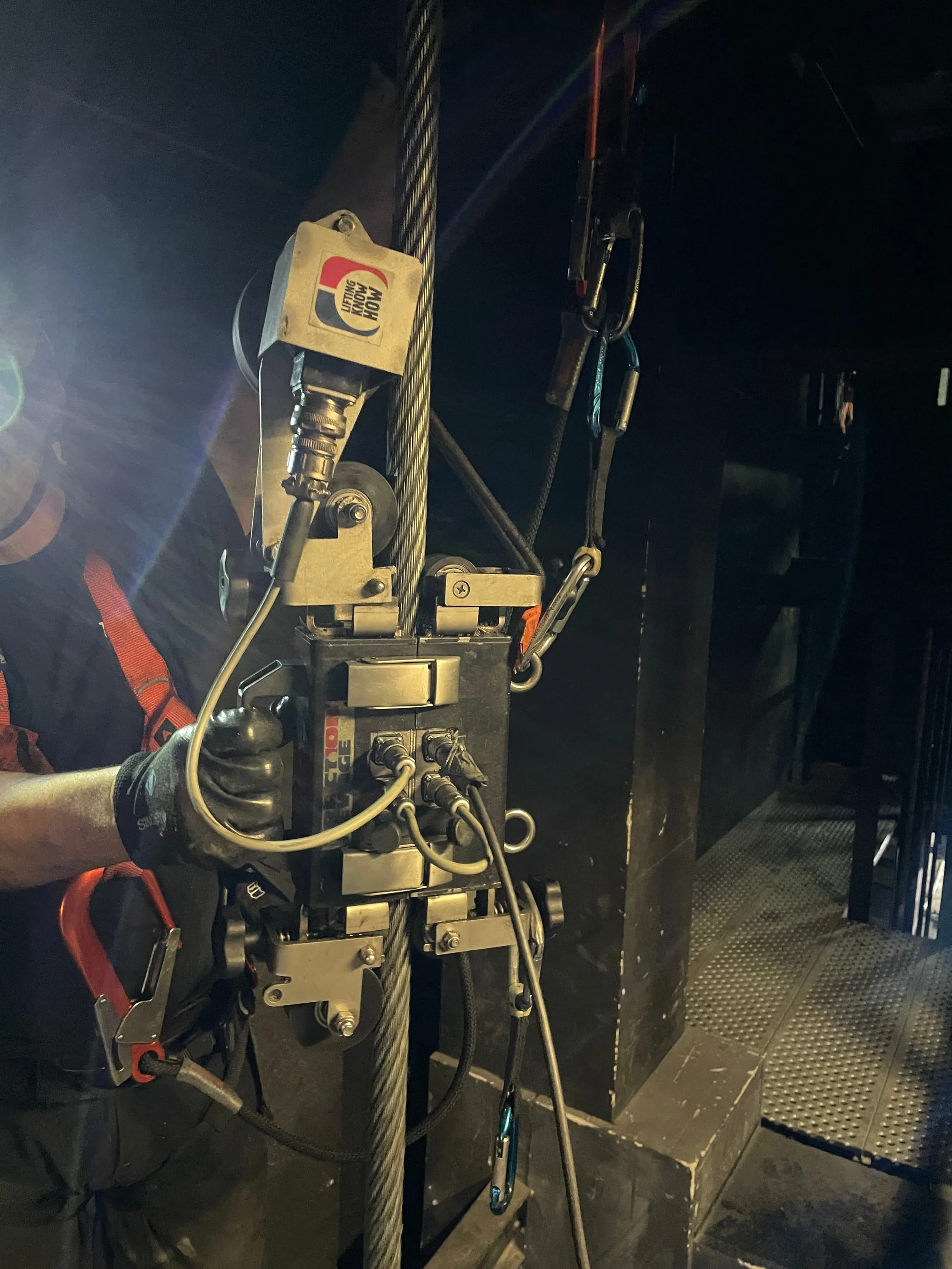

Our acquisition system consists of a measuring device and a data processing, storage, and display unit. This allows the user to analyze the collected data in real-time.

Sectors concerned by Magnetic Rope Testing

Elevators & Lifts

Elevators & Lifts

Industry

Industry

Hydraulic

Hydraulic

Mountain

Mountain

![]()

Cable stayed structures

![]()

Ports

![]()

Maritime

Nuclear

Installation of the device in spot mode (via technician) or permanent mode (device permanently installed)

Testimonial from SAPPI

The company Sappi, a paper manufacturer in Maastricht, trusted the expertise of Lifting Solutions Group to design its MRT solution.

Discover in detail how the Magnetic Rope Testing of the wire ropes of the company's 35 overhead cranes and gantry cranes was carried out.

Traction Levage is certified according to ISO9712 for the use of these magneto-inductive devices (MRT) and can now offer these services on your installations under MIT Level II.

We remain available to offer you various inspection possibilities and/or the implementation of such devices on your sensitive installations (mobile or permanent devices).